The goal of the Robot50 program is to provide resources to makers in the form of inexpensive and extendable projects that are accessible to the relative novice. The projects will build skills to assist makers in independently pursuing new projects. A concept brief can be found here (pdf file).

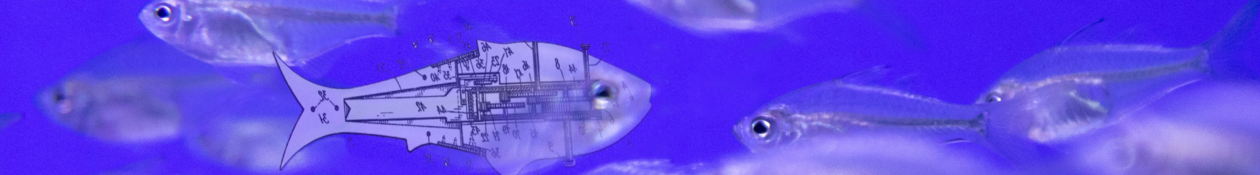

The first project of Robot50 is Bootstrap.